Injector machine in the Meat Processing Industry.

Meat injection machines play a crucial role in the production of cold cuts, hams, dry-cured meats, marinated products, and meat prepared for further thermal processing. These machines are adapted to the type of meat being processed. Whether pork, poultry, or beef and to the specific needs of the production line, including raw, cooked, or smoked products. A meat injection machine is a device commonly used in meat processing facilities to inject brine, curing solutions, or seasonings directly into the muscle tissue of raw meat (such as pork neck, ham, or chicken breast). The machine works by precisely injecting these liquids into the meat using multiple fine needles. As a result, it accelerates the curing process, enhances flavor, improves juiciness, and increases the yield of the final product.

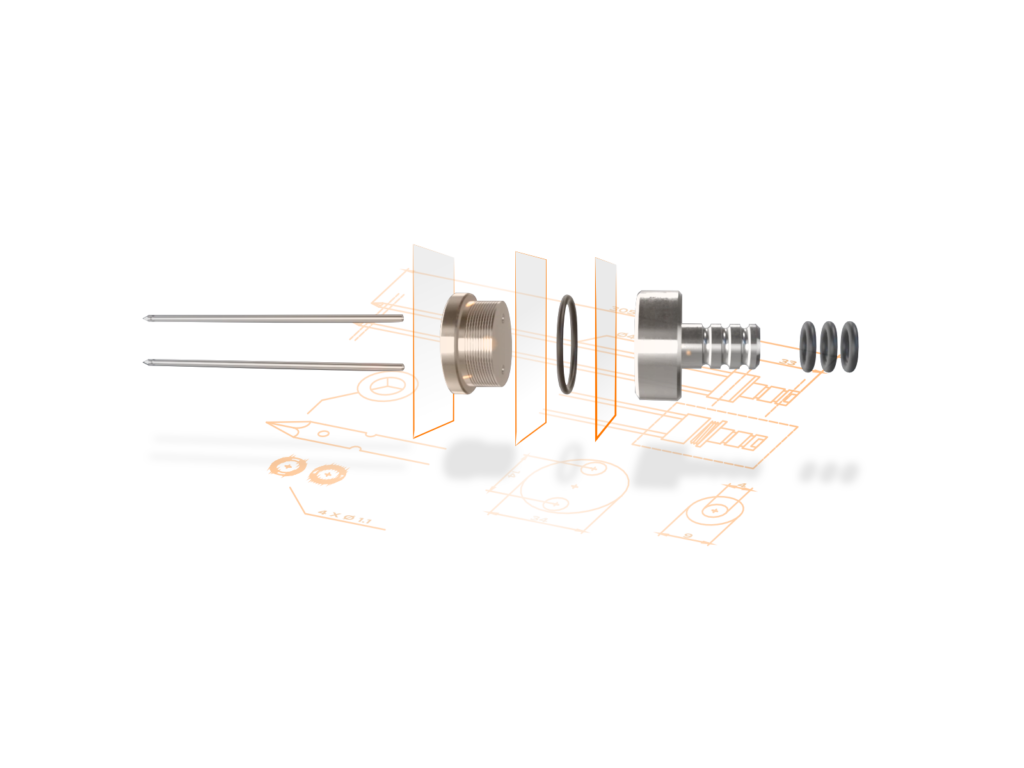

High-Quality Injection Needles

Our company specializes in manufacturing injection needles used in meat processing. These needles are a key component in ensuring both the efficiency of the injection process and the quality of the final product. High-quality needles deliver a uniform injection across the entire volume of the meat, ensuring consistent flavor, color, and texture. In contrast, poorly made needles with uneven holes or improperly drilled tips, can result in irregular brine distribution. This may lead to over-salted areas and under-cured sections, ultimately compromising product quality.

Quality

To avoid these issues, needles should be sharp, smooth, and well-polished to minimize muscle damage during injection. Dull or damaged needles may tear the meat, cause juice loss, and negatively impact the product’s appearance and sensory quality. Our needles are made from high-grade food-safe stainless steel, which ensures durability, corrosion resistance, and ease of cleaning. Any cracks, contamination, or breakage can pose serious biological or physical contamination risks, including the presence of foreign objects in the product a major concern in the food industry.

There are different types of needles available: solid, perforated, one-sided, or rotating. Their design and material quality must match the type of meat (e.g., tender poultry vs. dense pork neck) and the specific machine in use. Using the wrong type of needle head or one of poor quality, not only risks damaging the meat but can also overload or damage the injection equipment. Contact us today to find the right needle tailored to your production process, machine type, and meat product.

How the Meat Injection Machine Works: Step-by-Step Overview

Brine Preparation

First, the curing solution is prepared, typically composed of water, salt, nitrites, spices, phosphates, proteins, and sugars. It is then filtered and stored in a separate tank.

Meat Loading

First, the curing solution is. Next, raw meat is placed into the machine’s feed system, which moves it under the injection head.

Injection Process

The brine is injected into the meat using dozens or even hundreds of fine needles. The liquid is delivered under controlled pressure. The needles can be evenly spaced and designed to reach a specific depth within the meat. Depending on the model, they may be solid, perforated, or equipped with pulsation functions to enhance distribution.

Dose Control

Advanced control systems allow the operator to set the precise injection percentage (e.g., 10%, 20%, or 40% of the meat’s weight). This ensures consistency and adherence to recipe specifications.

Product Transfer Once injected, the meat is transferred to the next stage typically tumbling or massaging to further distribute the brine and enhance absorption.

Advantages of Using Meat Injector Machine.

Faster curing time from several days to just hours or minutes.

Improved penetration and distribution of functional ingredients.

Increased production efficiency higher yield of finished product.

Greater consistency and repeatability of the process.

Enhanced juiciness, color, and flavor of the meat.