Why Using Injector Food Machines.

In the context of food safety, the term “Injector Food” refers to the process of injecting food—typically meat—with functional solutions using specialized injection machines. This technology plays a vital role in enhancing both product quality and microbiological safety within the food industry.

Increases Food Safety

By injecting brines, marinades, spices, fats, or enzymes directly into the product, manufacturers can ensure greater product consistency and standardization. This level of control is essential for meeting today’s stringent food safety standards.

During the injection process, curing solutions often containing salt, nitrites, spices, and functional additives like antioxidants and stabilizers are delivered deep into the muscle tissue. This precise distribution helps inhibit the growth of harmful microorganisms such as Clostridium botulinum and Listeria monocytogenes.

Quality

In contrast, traditional dry-curing methods can take several days and often result in uneven penetration, increasing the risk of microbial spoilage. Injection, on the other hand, allows for fast, uniform curing, which significantly reduces microbial risk while enabling strict compliance with HACCP protocols.

Modern injection machines equipped with advanced needle system offer full control over injection parameters such as pressure, depth, volume, and needle distribution. As a result, each batch of meat maintains consistent composition and microbiological quality, which is critical for meeting standards like ISO 22000, BRC, and IFS.

Contact us to learn more about our injection needles and how they can optimize your food production process.

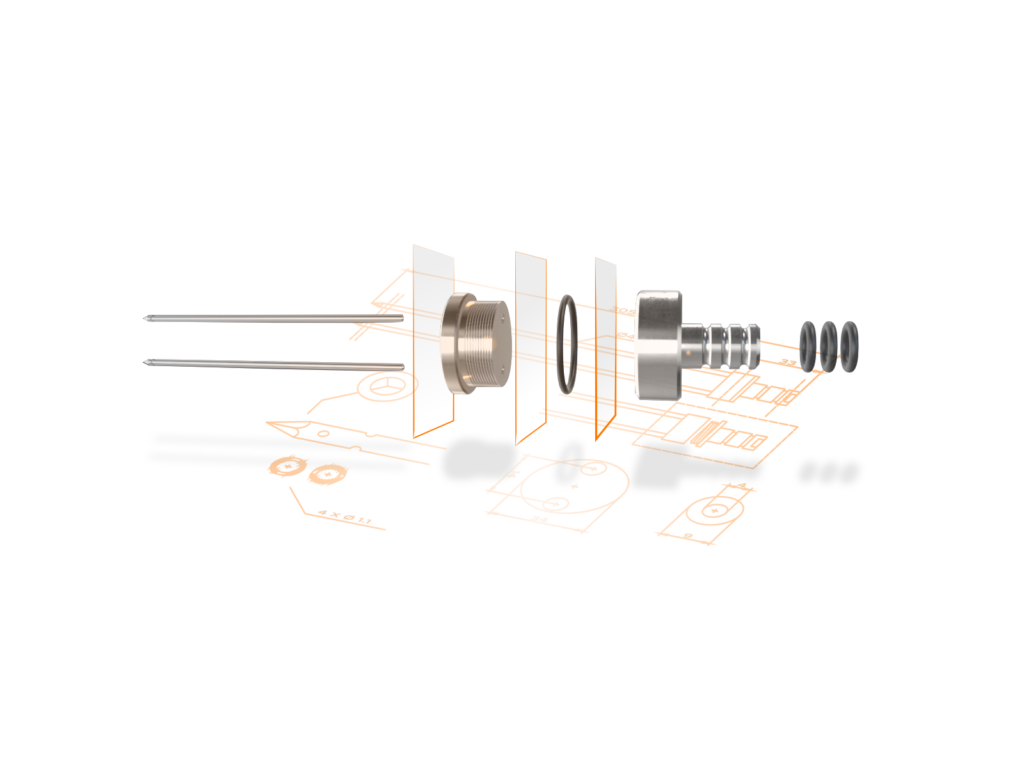

Injection Needle Quality

One of the most essential technological elements in the injector system is the injection needle. Needles made from premium materials such as AISI 316L stainless steel provide high resistance to chemicals, steam, and wear making them ideal for food grade applications

Thanks to advanced grinding and polishing technology, our needles prevent burr formation and micro-damage. As a result, they ensure precise perforation and allow for even brine flow throughout the meat. Additionally, the polished surface reduces friction and minimizes damage to meat fibers, preserving product integrity.

A Critical Component of the “Injector Food” Process

Process efficiency.

Food safety and hygiene.

Compliance with international. standards (HACCP, BRC, IFS).

Operational costs.

Final product quality.