Meat Marinating: Apply Modern Marination Technology in the Food Industry.

In large-scale meat processing, the meat marinating process is one of the most important technological stages. It plays a crucial role in determining the flavor, texture, shelf life, and overall quality of the final product. While marinating is a centuries-old concept, today’s industrial marination methods allow for an automated, controlled, and repeatable process. As a result, meat products can meet the strict demands of modern markets and international quality standards.

What Is Industrial Meat Marinating?

Meat marinating involves treating meat with a specially formulated marinade. Typically, the marinade contains water, salt, spices, fats, enzymes, and functional additives such as stabilizers and antioxidants. In some cases, the mixture also includes ingredients that enhance texture and color. The objective of this process is to improve flavor, juiciness, tenderness, color stability, shelf life, and microbiological safety.

To ensure these outcomes, meat marinating must strictly follow HACCP principles, with all parameters carefully documented and monitored. The process takes place under controlled conditions of temperature, time, and pressure, which ensures repeatability and microbial safety. Additionally, the marinade components must comply with food safety regulations, and the equipment must be regularly cleaned and serviced.

In industrial settings, meat marination is performed using specialized machines, including:

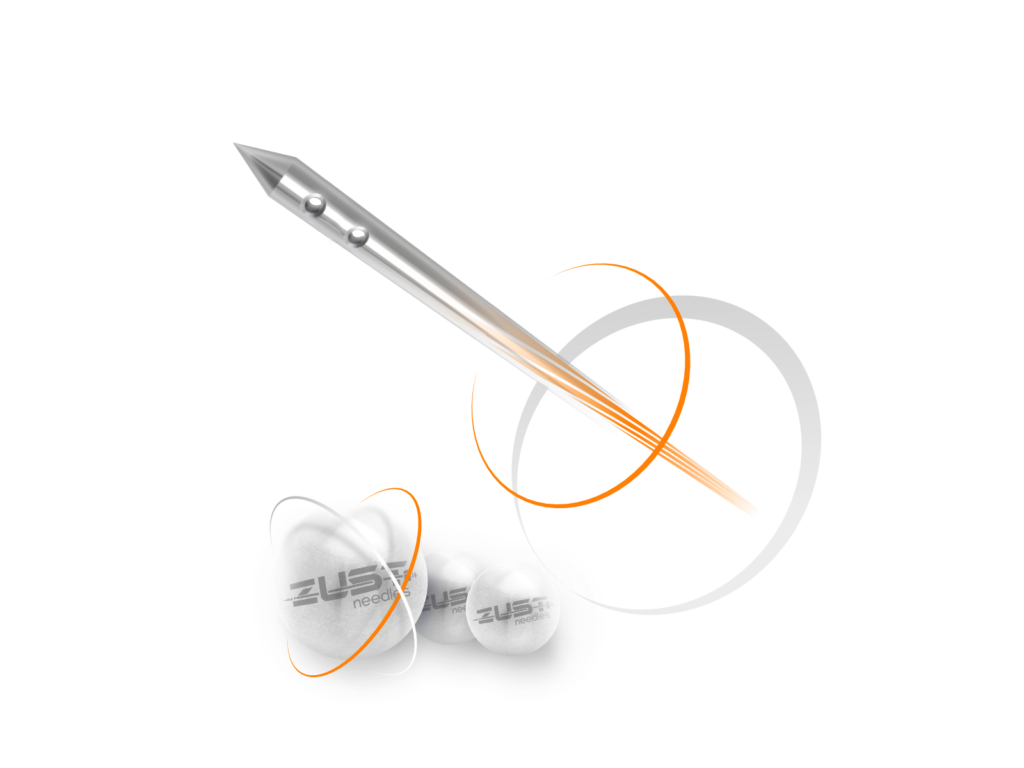

Injection machines (injectors) – These deliver the marinade deep into the meat using multiple precision needles.

Mixing and tumbling machines (tumblers and massagers) – These aid in the absorption of the marinade by mechanically loosening the muscle fibers.

Vacuum systems – These improve marinade uptake by reducing air pressure, allowing deeper and more uniform contact with meat fibers.

Injection Needles: A Key Component in the Meat Marinating Process

The quality of the needles used for meat injection plays a critical role throughout the marination process. In injector systems, manufacturers rely on high-performance needles that meet stringent hygienic and technical standards. These are most often made from premium AISI 316L stainless steel, which offers exceptional resistance to corrosion, steam, and aggressive brine solutions.

Moreover, this high-grade steel maintains durability even under intense use and frequent sanitation. The needles undergo precise grinding and polishing, which gives them a smooth, burr-free surface. This minimizes friction, reduces damage to the muscle structure, and eliminates potential contamination risks. As a result, the injection solution flows evenly through the side or end openings, allowing for full control over the quality and consistency of each batch.

In summary, high-quality needles are not just about equipment longevity, they are essential to safety, hygiene, and the overall efficiency of the injector meat process.

Our Needles. Would you like to improve the injection process in your facility? We provide customized needles and components suitable for any injection machine and type of meat. We deliver quality, durability, and expert technical support to optimize your production.

.

Meat Marinating: A Summary

In the meat industry, meat marinating is a technologically advanced process that enables producers to deliver high-quality, consistent meat products. By combining modern methods such as injection, tumbling, and vacuum marination, processors can achieve the perfect balance of flavor, texture, shelf life, and microbiological safety.

Given today’s rising consumer expectations and increasingly strict quality standards, professional meat marinating is no longer just a support process, it has become a core pillar of success in the meat production industry.