Advantages of Injected Meat in the Meat Industry.

Injected meat, typically enhanced with brine or marinade, often outperforms non-injected meat in various applications. However, “better” depends on context—flavor, shelf life, juiciness, or cooking results. In this article, we explore why injected meat is often preferred in food production and food service industries.

First of all, injected meat retains more water. As a result, it stays moist and tender after cooking, especially in lean cuts like chicken breast or pork loin. In addition, injection solutions include salt, spices, and functional additives that spread evenly within the meat structure. This consistency creates a more intense and reliable flavor in every bite.

Moreover, specific ingredients—such as nitrites, phosphates, and antioxidants—can inhibit bacterial growth and extend shelf life. Consequently, the meat can be stored and transported more safely across supply chains.

Quality

What’s more, injected meat cooks more evenly and quickly, making it easier to achieve the desired texture. This is especially beneficial in restaurants and industrial kitchens, where time and cost efficiency are essential. Furthermore, the injection process is technologically controlled. Every batch receives the same level of salt, moisture, and flavor, which is critical in large-scale production.

If you are considering implementing or optimizing an injected meat process, don’t hesitate to contact us. Our experienced consultants will help you find the best solution for your specific production needs.

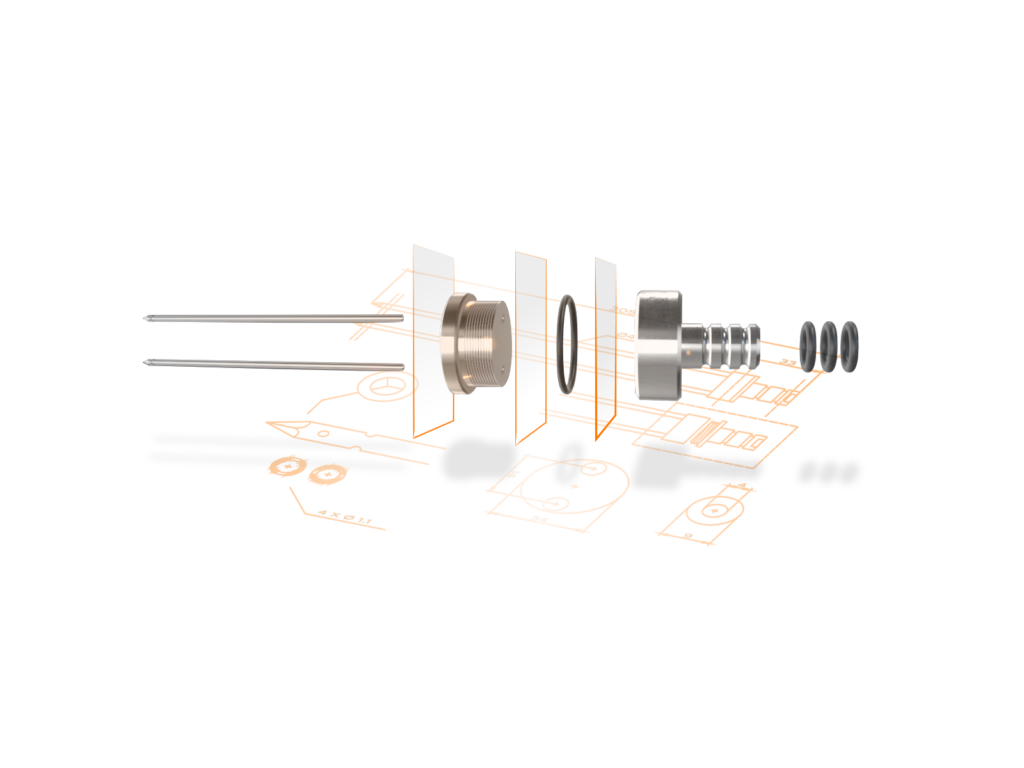

Contact us to learn more about our injection needles and how they can optimize your food production process.

What About the Disadvantages of Injected Meat?

Despite its many technical and functional benefits, injected meat comes with some controversy. For certain consumers and professionals, it represents a trade-off between quality and efficiency.

Sometimes, over-injection or poorly formulated brines can weaken muscle structure. As a result, the meat may become too soft or even spongy, which reduces its sensory appeal.