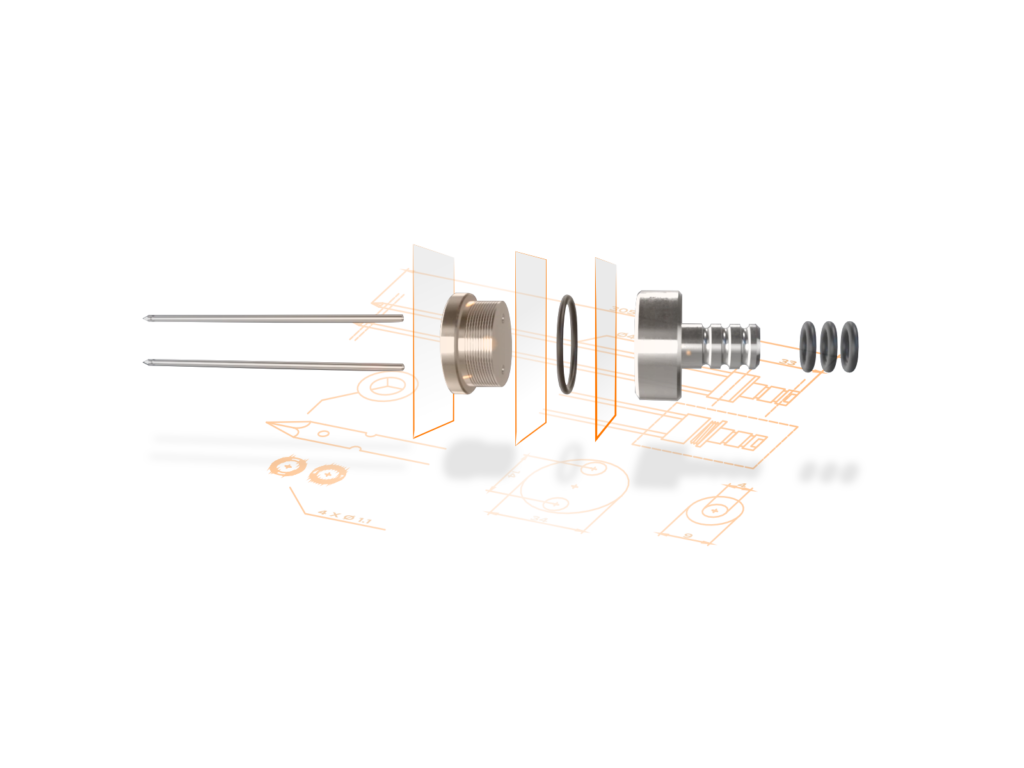

Injector Needles for Food Processing Precision and Durability by ZUST Needles.

At ZUST Needles, we specialize in manufacturing professional injector needles for food processing systems. Our needles serve meat, both boneless and bone-in as well as poultry and fish. Importantly, we design each needle to work seamlessly with industrial brine injection systems. As a result, they deliver precise brine distribution while preserving the meat’s structural integrity.

All of our needles are made from high-quality AISI 316 stainless steel. This material is widely recognized for its excellent corrosion resistance and mechanical strength. In addition, it is entirely safe for contact with food. Consequently, our needles offer a unique combination of hardness and flexibility. Their durability and efficiency significantly exceed traditional solutions.

Custom Injector Needle Configuration Without Extra Costs.

We proudly offer a wide range of configurations. For instance, you can select from various tube diameters and wall thicknesses. Additionally, we provide single-hole or multi-hole versions with customized hole number, placement, and diameter. We also offer reinforced tips designed especially for bone-in products.

If you require a custom-made design, we are ready to help. We deliver tailored solutions with no additional design fees. Most importantly, we adapt every needle to your specific injector system and product type. Feel free to contact us anytime.

Why Choose ZUST Injector Needles?

We use durable, food-safe materials approved for direct food contact. As a result, our needles ensure precise injection with consistent quality and repeatability. Furthermore, we offer personalized designs for all types of injection machines. The hygienic, efficient construction performs reliably even under demanding processing conditions. That’s why our needles are trusted in meat, poultry, and fish applications.

Contact us today to discover how ZUST injector needles can boost your production and elevate product quality. We offer expert consultation and tailored solutions for every processing line.

Injector Needles Quality

Thanks to razor-sharp tips and smooth surfaces, our needles penetrate muscle tissue effortlessly. This reduces fiber damage, minimizes brine leakage, and eliminates visible marks in the final product. Consequently, you get meat products with better texture, appearance, and consumer appeal.

Each injector needle also features smooth internal channels. These ensure uninterrupted brine flow during operation. In addition, electro-polished internal and external surfaces reduce bacterial buildup. As a result, product hygiene improves, and overall needle life extends.