Brine Injector Technology: Precision Brine Injection and Its Impact on Food Product Quality.

Modern food production demands solutions that are not only efficient and hygienic but also capable of improving product quality. Today, technology plays a crucial role not just in optimizing processes, but also in enhancing the final product. One such key innovation is the brine injector—a device used to inject meat, poultry, or fish with specialized brine solutions that typically contain water, salt, spices, and functional additives.

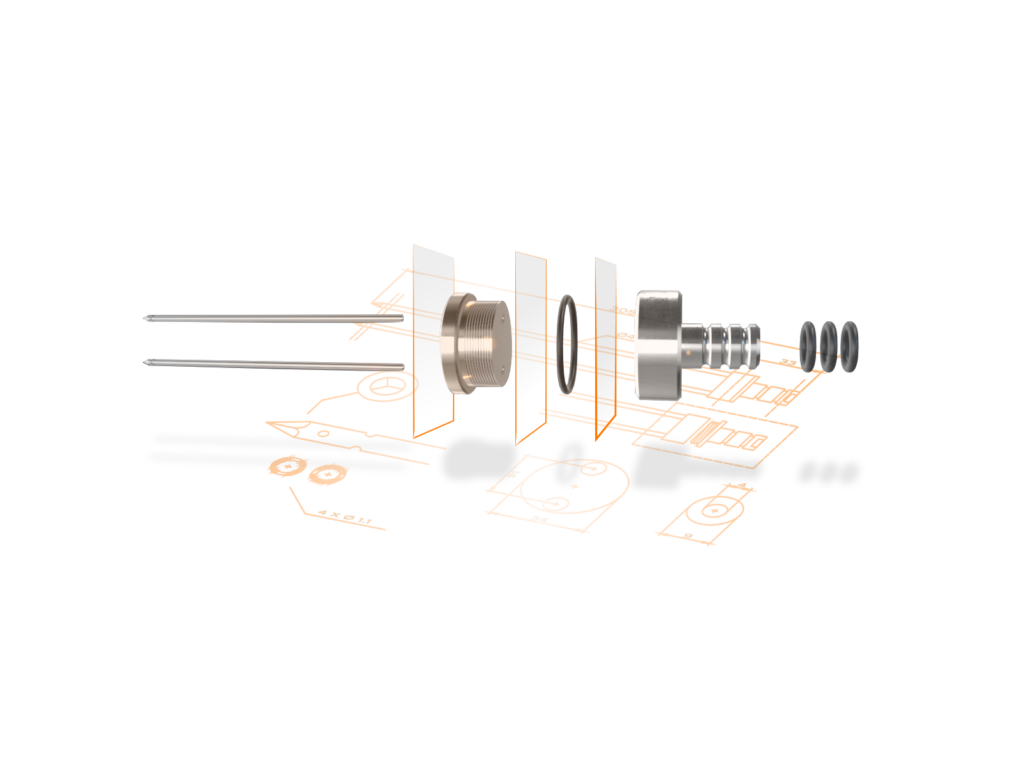

To fully appreciate its benefits, it’s important to understand how brine injector technology works. The system uses a machine equipped with a set of fine needles that deliver the brine deep into the muscle tissue. As a result, active ingredients are evenly distributed throughout the product, which improves its flavor, texture, and shelf life.

Moreover, today’s brine injectors are often fitted with advanced control systems. These systems allow precise regulation of injection depth, pressure, and liquid dosage. Consequently, the injection process becomes not only highly accurate but also fully repeatable—an essential factor in large-scale industrial food production.

Key Benefits of Brine Injector Technology .

- Enhanced juiciness and texture

Brine naturally helps meat retain moisture, leading to superior sensory qualities during cooking. - Consistent flavor and standardization

Even distribution of seasoning ensures every bite delivers the same high-quality taste. - Extended shelf life

Carefully selected ingredients in the brine solution can slow spoilage and inhibit microbial growth, improving product safety. - Improved processing efficiency

Brined meat matures more quickly and behaves more predictably during thermal processing, making production more consistent and controllable.

Quality

Additionally, one of the standout advantages of modern brine injectors is their versatility. These systems can be adjusted to handle a wide variety of products—from large meat cuts and whole poultry to delicate fish fillets. In this context, it’s also worth highlighting features like automatic cleaning systems (CIP – Clean In Place), which ensure the highest standards of hygiene without requiring manual disassembly.

Contact us to learn more about our Brine Injectors and how they can optimize your food production process.

Brine Injector Solutions Tailored to Your Needs .

In conclusion, a properly executed brine injection process can significantly enhance the quality of your final product, offering a valuable competitive edge in today’s demanding food market. The brine injector is more than just a production tool; it is a transformative technology that directly shapes the flavor, safety, and shelf stability of the products we consume every day.

Contact us today to find the most effective brine injector technology for your processing plant. We’ll help you select the optimal solution to meet your production goals with precision and efficiency. .