The Role of the Needle Head in the Food Industry.

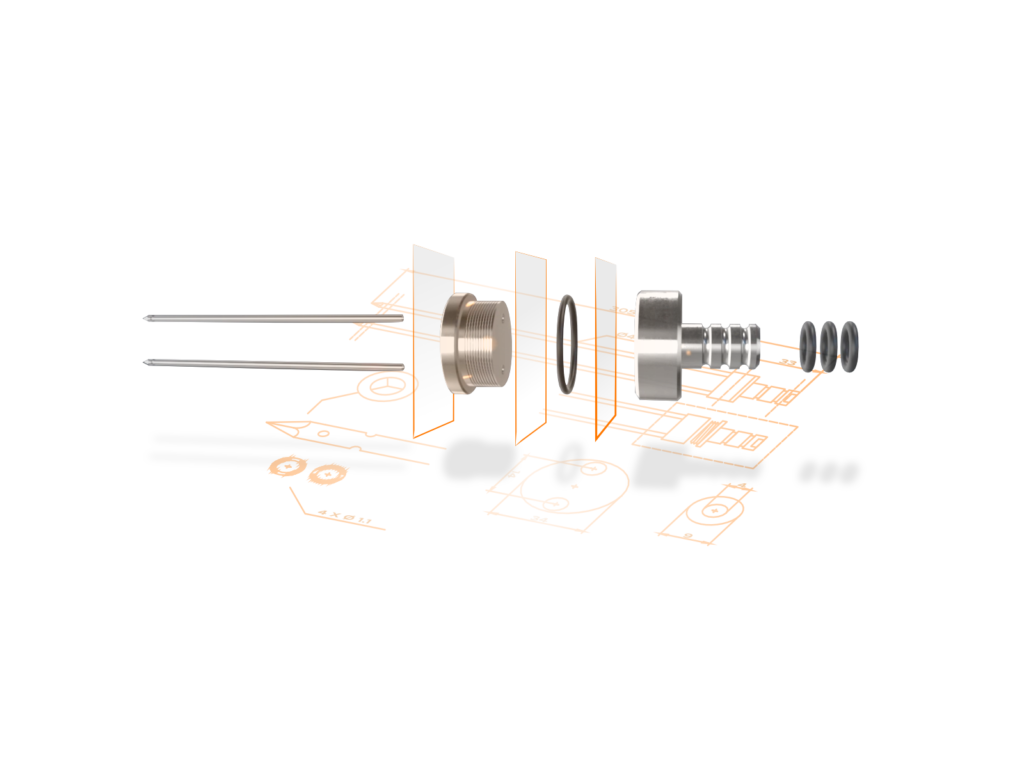

Modern food production continuously strives to increase efficiency while maintaining the highest standards of quality and safety. One of the key technologies supporting this goal is the injection machine—widely used in the processing of meat, poultry, and fish. At the heart of these machines lies the needle head, a precision component responsible for delivering brine solutions, marinades, or enzymes deep into the product.

The needle head is a modular unit that contains an array of injection needles. Depending on the application and the type of raw material, a needle head may house anywhere from a few to several hundred needles.

Types of Needle Heads.

There are three primary types of injection needles used in food processing:

Solid needles – best suited for low-viscosity liquids.

Side-perforated needles – designed to ensure even distribution of the brine.

Specialized needles – such as anti-clogging designs for injections involving solid particles.

The applications of needle heads in food injectors are remarkably broad. Most notably, they play a central role in injecting meat and poultry, enhancing flavor, texture, and juiciness while extending shelf life. Additionally, they are highly effective in marinating fish, allowing spices and functional additives to absorb more quickly and evenly.

Moreover, many facilities use needle heads for enzymatic injections, a process that accelerates tenderization or aging—especially valuable in short-cycle production environments. Thanks to ongoing technological advancements, modern needle heads have become even more precise and multifunctional.

For instance, many new models include CIP (Clean-In-Place) systems that streamline sanitation procedures. Additionally, integrated pressure and flow sensors provide real-time monitoring of the injection process, ensuring consistent and controlled results.

Another notable innovation is smart needle control technology, which activates injection only when the needle detects product beneath it. This feature proves invaluable when handling irregularly shaped raw materials, guaranteeing precise and waste-free injections. In sum, all of these capabilities and innovations position the needle head as an indispensable component of today’s food production lines.

Contact us to learn more about our injection needles and how they can optimize your food production process.

Key Qualities of a High-Performance Needle Head.

Our company specializes in the production of custom needle heads. If you’re looking for needle solutions tailored to your specific injection system or food product, feel free to reach out. We’ll help you select the most optimal configuration for your needs.

To function efficiently and hygienically, a needle head must possess several essential qualities:

- Precise needle spacing – ensures uniform injection across the entire batch.

- Corrosion resistance – achieved through the use of food-grade stainless steel.

- Easy disassembly and cleaning – critical for compliance with HACCP sanitation protocols.

- Adjustable depth and pressure – fine-tuned to suit different product types.